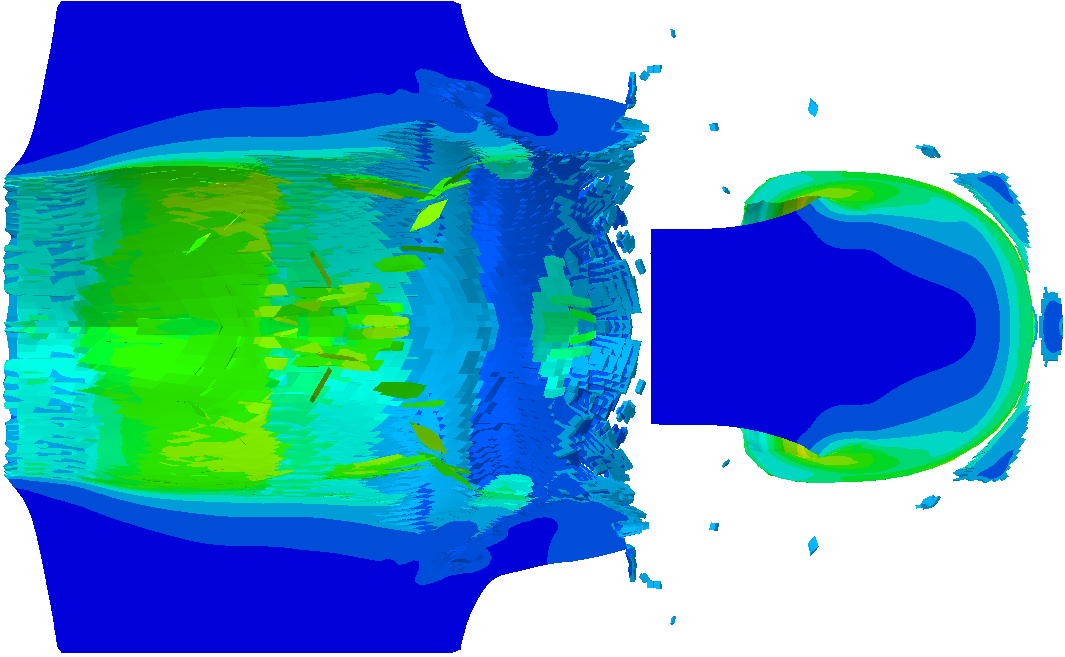

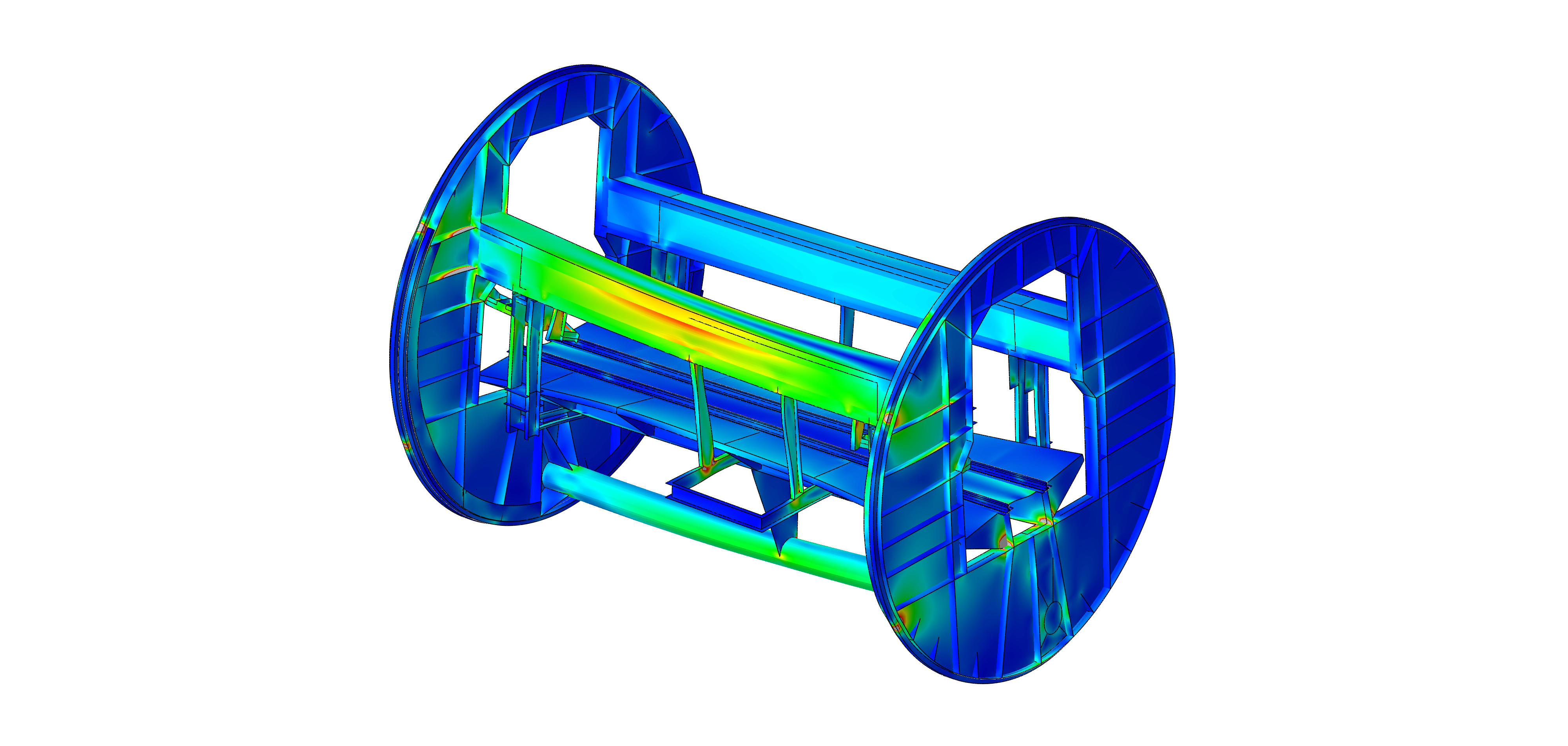

Finite Element Analysis (FEA)

Finite Element Analysis is an extremely powerful tool that can be used in the assessment of operating equipment, components and structures. FEC select the most appropriate analysis technique, and software, to solve the problem at hand. From simple beam element structures through to dynamic explicit damage and fracture modelling, FEC have the experience to get the job done. FEC complete all FEA in accordance with industry best practice and provide comprehensive reports to fully document our methods and provide transparency for our clients.

Applications

FEA is used where conventional design by rule or fundamental calculations do not provide sufficient detail or become to cumbersome to complete the task at hand. So for complicated structures, highly complex loadings, transient modelling and combinations of the above, FEA makes sense. All of our engineers use FEA on a daily basis as part of performing design tasks, resulting in very high software proficiency. The collective FEA experience within FEC results in a highly efficient design process and ultimately a better outcome for our clients in a shorter amount of time.

FEA sees application in the design of pressure equipment, structures and machine components. Where the application of FEA is derived from a Standard (e.g. AS1210 or ASME VIII Division 2), those techniques are comprehensively applied to ensure all protections with the code are satisfied.

Prior Experience

FEC have completed over 1000 FE design tasks over the last 5 years and throughout this time have completed:

- Elastic stress analysis

- Elastic plastic stress analysis

- Coupled temperature-displacement analysis (heat transfer and stress)

- Dynamic explicit fracture simulations

- Transient elastic plastic simulations

- Eigenvalue, linear perturbation procedures

- Riks post-buckling simulation

- Stress intensity calculation and fracture assessment

- Product manufacture and forming simulations

- Seismic Spectral Analysis

- Natural frequency analysis

- Analyses in accordance with AS1210, ASME VIII Division 2 Part 5, AS4100, API579

Capabilities

- Nozzle loading assessment

- Fatigue life calculation

- Protection against buckling

- Protection against ratcheting

- Protection against plastic collapse

- Design by analysis of pressure equipment

- Acoustic induced vibration and associated fatigue damage

- Fracture mechanics stress intensity factor and load ratio calculation

- Natural frequency and resonance calculations

- Thermal analysis

Head Office (Brisbane)

ABN 30 161 215 372

PO Box 3083

Newstead, 4006,

Qld, Australia

14 Jordan Terrace,

Bowen Hills, 4006,

Qld, Australia

All of the content on this website is the property of FEC or used with permission from our clients. Reproduction or use of this content without express written permission from FE Consultants is prohibited.