FEC was approached by one of our clients requiring verification of the axial load capacity for a proprietary developed buttress thread for use in well casing. The design was unique in that it required creating a flush joint for the casing as opposed to using the standard approach of threaded couplings. The thread was based on a standard API 5B buttress casing thread form. The client required engineering design approval for the axial load capacity of the joint.

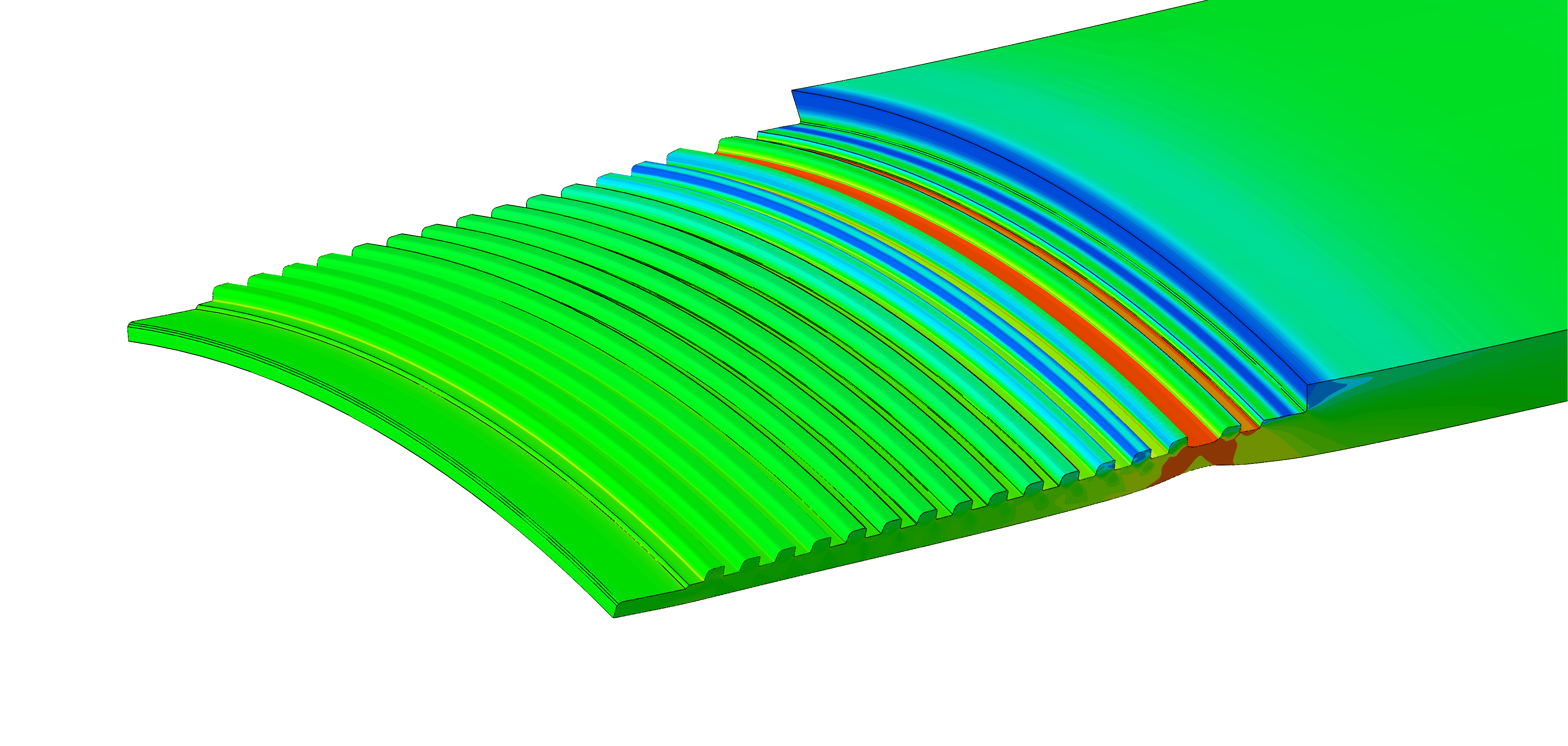

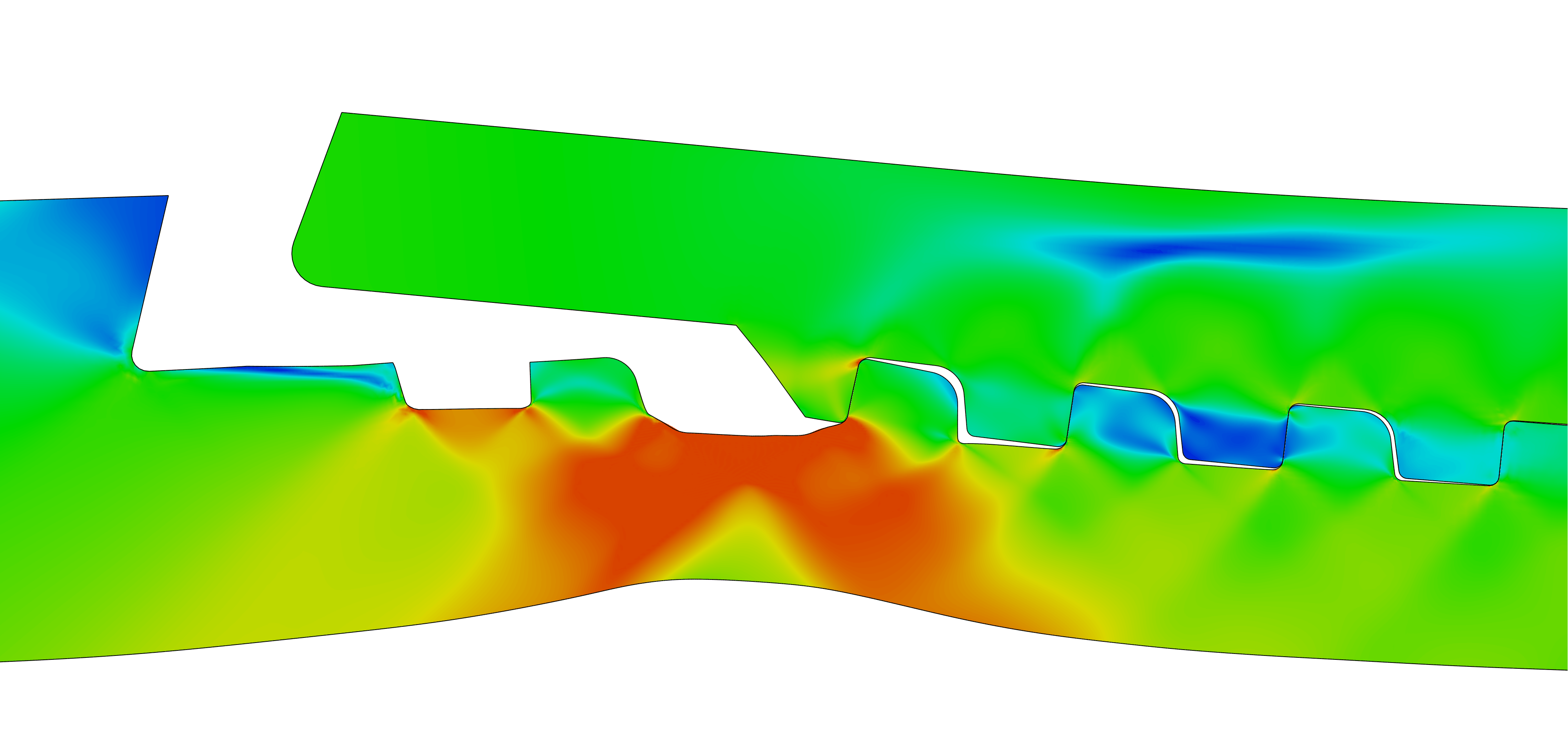

The axisymmetric models were created and considered direct contact interaction between the profiles of both the pin and box threads. Due to the efficiency of the axisymmetric method used, high levels of mesh refinement could be utilised at the root of all teeth. Initial load capacity calculations using conventional methods produced overly conservative results with respect to physical testing.

Noting the conservatism in traditional methods, FEC used an elastic plastic material model to consider the material ductility, which allowed for more realistic simulation of the thread contact surface under large displacement. The material model was developed based on the properties of API 5L Grade B and the plasticity model as defined in ASME II Part D; a realistic true-stress verse true-strain curve for use in the yield criteria (Mises plasticity definition).

The design was evaluated for protection against plastic collapse and local failure based on the methods of ASME VIII Division 2 – Part 5. Protection against plastic collapse required convergence of the solution with material plasticity, large displacement theory and a prescribed load factor. The model was run to failure and the last converged step was taken as the plastic collapse limit. Protection against local failure required consideration of the material strain limit and the tri-axial stress state for each element in the model. When material is under tri-axial stress, the Mises yield criterion will not accurately capture non-ductile failure modes. For this reason FEC developed a post-processing module for FE models which reviewed the requirements for local failure.

By applying advanced analysis methods, FEC determined the load rating for 3 sizes of threaded joints. The benefit for our client was a quick and efficient rating process without the need for fabrication and batch testing of the numerous joints. This allowed for faster time to market for their product and reduced cost when compared to physical testing.